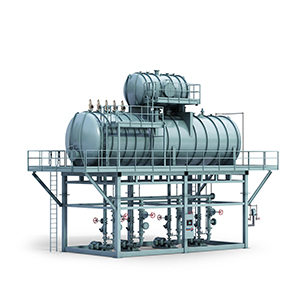

TrayMaster Deaerator

- Vertical or horizontal tray column design

- Largest capacities available

- Most effective at oxygen removal

- Model TMV: 30,000 – 500,000 lb/hr

- Model TMH: 500,000 – 1,000,000 lb/hr

- On/off and variable speed pumping

The TrayMaster deaerator is a pressurized, low-maintenance system designed to remove dissolved oxygen in boiler feedwater and eliminate carbon dioxide. This deaerator is offered in vertical and horizontal tray configurations.

- Boiler Feed and Condensate Recovery Systems Brochure(Literature)

- Installation Manual - Deaerators and Surge Tank(Technical Data)

- Maintenance Manual - Deaerators and Surge Tanks(Technical Data)

- Steam Reference Guide(Literature)

- TrayMaster Boiler Book(Technical Data)

- TrayMaster Specifications(Technical Data)

- TrayMaster Vertical Deaerator ADSK Files(Drawings)

- TrayMaster Vertical Deaerator DWG Files(Drawings)

- TrayMaster Vertical Deaerator STEP Files(Drawings)

- Product Overview

- Related Resources

- Applications

- Less mechanical movement of deaerator components

- Two-stage deaeration in a common vessel

- Exceeds ASME recommendations for oxygen level

- Integral level control automatically introduces cold water makeup

- Supplement condensate only when necessary to meet boiler demand

- On/off or variable speed pumping

The TrayMaster deaerator design is recognized as the most versatile and efficient method of reducing dissolved oxygen content in boiler feedwater to levels less than .005 cc/liter (7 ppb) while also removing carbon dioxide. Built of corrosion-resistant alloys for lifetime service, the deaerator employs advanced principles of gas removal proved to be the most effective and economical to every boiler owner. Vessels are all factory tested, then assembled and broken down for shipment and ease of installation. All of Cleaver-Brooks deaerators can be equipped with a wide range of options from basic manual controls up through full advanced digital operation depending on the needs of the system. Equip your Deaerator with the ADAC control system to provide the most advanced operation of your feed systems.

WEBINARS

Boiler Room Installation Considerations for Safety, Reliability, and Efficiency →

Learn about several aspects that help to ensure proper boiler installation.

Pressurized Condensate Systems: Increasing Steam System Thermal Cycle Efficiency →

Learn about the benefits of pressurized condensate systems, different application methods and equipment, and how to control and apply it to a new or existing system.

- Process Steam

- Industrial Process

- Building Heat

- Sterilization

- Humidification

- Waste Heat Recovery

- Hospital and Healthcare

- Power and Utilities

- Refineries and Petrochemical

- Laundry and Dry Cleaning